2021 – Organizational Update

Xylergy SA has acquired all technology, name rights and assets of Xylowatt SA.

The NOTAR® story will continue under the umbrella of Xylergy SA. Check out the new website www.xylergy-group.com

We would like to ensure all customers and business partners of our unlimited support to their journey of decreasing the carbon footprint and increasing sustainability.

You can reach us under sales@xylergy-group.green

This website will be updated soon.

Xylowatt developed the NOTAR® reactor, an innovative and patented technology that produces a clean tar free syngas from natural and recycled wood biomass gasification.

Biomass

Locally available natural and recycled wood chips are valorised by the NOTAR® gasifier.

Gasification

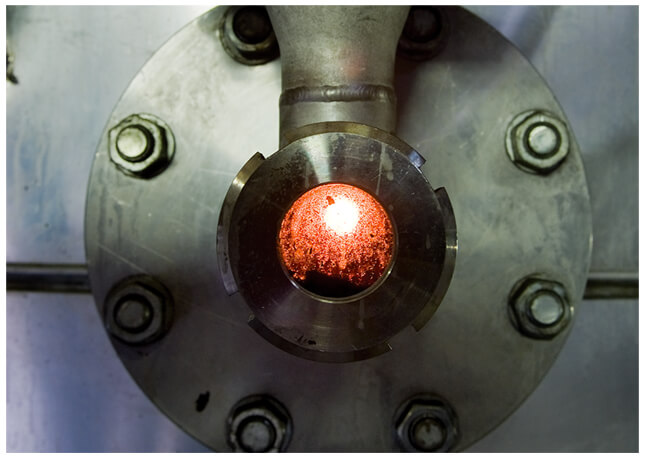

The NOTAR® gasification process is a unique and patented technology to transform biomass into renewable energy.

Syngas

The tar free syngas produced by the NOTAR® is of high quality and can be safely injected in cogeneration engine.

Energy Production

Combined with cogeneration engines, our NOTAR® units supply our clients with renewable energy. Xylowatt develops turnkey projects for biomass gasification plants with a power range of 750kWe to 2000kWe.

Electricity covers local needs or can be sold on the electrical grid

Heat is available for a wide range of heating applications

Cold from unused heat, is valuable for cooling applications

Looking for a sustainable

gasification solution ?

Want to join our team ?

We are looking for new talents.